A valve seat is the surface inside a valve against which the closure element (plug, disc, ball, or gate) presses to stop the flow of fluid. It is one of the most critical components in any valve because it determines how well the valve can shut off, resist wear, and maintain long-term sealing performance.

Table of Contents

ToggleWhat Is a Valve Seat? (Simple Definition)

A valve seat is the mating surface that forms a seal with the valve’s moving part (called the closure member). When the valve closes, the closure member presses against the valve seat to block flow.

Where You Find Valve Seats

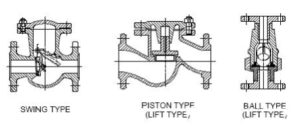

Valve seats exist in virtually all valve types:

Ball valves → ball seals against PTFE or metal seats

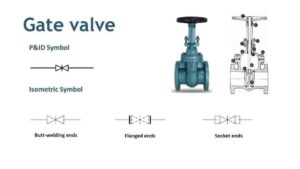

Gate valves → gate wedges between two metal seats

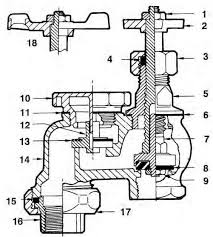

Globe valves → plug sits on a conical seat

Check valves → disc closes against the seat

Control valves → trim includes plug + seat

Materials Used for Valve Seats

Valve seats are engineered for durability, chemical resistance, and sealing:

Soft (Resilient) Seats

Used in ball valves & butterfly valves for bubble-tight sealing.

PTFE (Teflon)

RPTFE

EPDM

NBR

Viton (FKM)

Pros: Excellent seal, zero leakage (API 598)

Cons: Limited temperature and wear resistance

Metal Seats

Used in high-temperature, high-pressure, or abrasive service.

Stainless steel (304/316)

Stellite

Alloy 6

Monel

Hastelloy

Pros: Durable, high-temp capable

Cons: Allowed leakage (Class V, VI)

Functions of a Valve Seat

✔ 1. Sealing

Provides the primary isolation barrier to stop the flow.

✔ 2. Alignment

Ensures the closure member aligns properly for consistent operation.

✔ 3. Erosion & Wear Protection

Protects the valve body from corrosion and fluid erosion.

✔ 4. Replaceability

Many valve seats (especially ball valves) are removable for maintenance.

Types of Valve Seats

1. Integral Seats

Machined as part of the valve body.

Pros: Strong, no loose parts

Cons: Hard to repair

2. Renewable Seats

Threaded or pressed into the body.

Pros: Easy to replace

Cons: Higher cost

3. Soft Seats

Polymer or elastomer sealing ring.

Pros: Tight shutoff

Cons: Lower temperature limits

4. Metal Seats

Hard-faced metallurgical surfaces.

Pros: High durability

Cons: Not fully bubble-tight

Why Valve Seats Fail

Erosion from sand or slurry

Cavitation damage

High-velocity flow

Corrosion

Over-torquing

Thermal cycling

Poor material selection

How to Choose the Right Valve Seat

Select based on:

Temperature

Pressure

Media (chemical, abrasive, sanitary)

Required leakage class (ANSI/FCI 70-2)

Operation frequency

Flow velocity