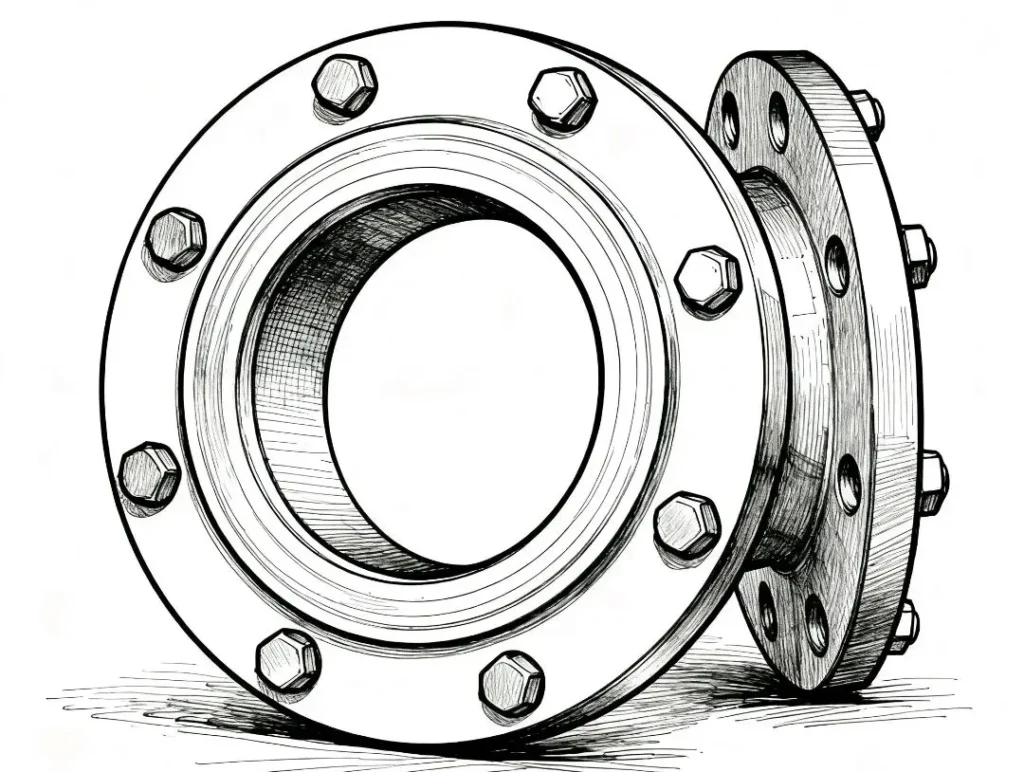

In the world of industrial piping, the secret to a leak-free connection often lies in the microscopic details of the flange face. Known colloquially as “Flange Water Lines” (or more technically as a serrated finish), these fine grooves are essential for sealing low-pressure systems using soft gaskets.

While modern technology has introduced advanced metal seals for high-pressure environments, the “water line” remains a cornerstone of industrial sealing for approximately 80% of global piping connections. In this guide, we explore the mechanics, standards, and critical dos and don’ts of flange water lines.

Table of Contents

ToggleI. Definition: What are Flange Water Lines?

Flange water lines are precision-machined grooves on the Raised Face (RF) of a flange. Their primary purpose is to create a “micro-interlocking” effect with soft gaskets.

Modern Technical Standards:

Early industrial water lines consisted of 2–4 deep V-shaped grooves (approx. 1mm deep). Today, the industry follows standardized serration profiles:

ASME B16.5 (American Standard): Depth of ~0.05mm, pitch of 0.45–0.55mm, with a surface roughness of Ra 3.2–6.3 μm.

DIN Standards (German Standard): Depth of 0.4mm and pitch of 0.8mm.

Precision Requirements: High-quality water lines must maintain flatness errors below 0.1mm. Statistics show that every 0.1mm of unevenness can increase the leak rate by nearly 10%.

II. The Mechanics of Sealing: Why Use Grooves?

Micro-Interlocking: Under bolt load, the soft gasket material is “squished” into the grooves, creating a mechanical bond that prevents gasket “blowout” or lateral movement.

The Labyrinth Effect: The concentric or spiral grooves create a tortuous path (a labyrinth), significantly increasing the resistance for any media attempting to escape.

Pressure Distribution: Serrations help guide the bolt’s pre-load evenly across the gasket surface, preventing localized stress concentrations that could crush the gasket.

Thermal/Pressure Buffering: The grooves provide microscopic expansion space for the gasket during temperature fluctuations, maintaining the seal’s integrity.

III. Flange Face Serration & Gasket Compatibility Matrix

“Are you matching your gaskets correctly? Our Flange Serration Matrix covers the essential standards for ASME B16.5 and DIN flanges. Improper gasket seating on a serrated face is the leading cause of industrial leakage. Download our guide to ensure your 1″ to 24″ flanges are sealed for safety and longevity.”

The success of a flange water line depends entirely on matching the right gasket material to the serration depth:

| Gasket Category | Gasket Material | Ideal Flange Finish (Serration) | Compatibility Rating | Technical Reason |

| Non-Metallic (Soft) | Compressed Fiber / Non-Asbestos | Serrated (Ra 3.2-6.3 μm) | ⭐⭐⭐⭐⭐ | Fibers “bite” into grooves to prevent blowout. |

| Non-Metallic (Soft) | Flexible Graphite | Serrated (Ra 3.2-12.5 μm) | ⭐⭐⭐⭐⭐ | Graphite flows into grooves to create a “labyrinth” seal. |

| Non-Metallic (Soft) | Virgin or Expanded PTFE | Fine Serrated (Ra 3.2 μm) | ⭐⭐⭐ | Deep grooves can tear the PTFE layer; requires high bolt load. |

| Semi-Metallic | Spiral Wound Gasket (SWG) | Smooth (Ra 1.6-3.2 μm) | ❌ DANGEROUS | Serrations can damage the metal windings and cause leaks. |

| Semi-Metallic | Kammprofile / Grooved Gasket | Smooth (Ra 1.6-3.2 μm) | ❌ PROHIBITED | Grooves on gasket + grooves on flange = No seal. |

| Metallic | Ring Type Joint (RTJ) | Cold Finish (Ra 1.6 μm) | ❌ PROHIBITED | Metal-to-metal seals require near-perfect smoothness. |

CRITICAL RULE: Never use water lines with metal gaskets (such as Spiral Wound Gaskets or Ring Type Joints). The hard metal layers will be scratched by the serrations, destroying the seal.

IV. Application Scenarios & Contraindications

When to Use Water Lines:

Low to Medium Pressure: PN ≤ 4.0MPa (or Class 150/300).

Media: Water, air, low-pressure steam, and non-corrosive liquids.

Industries: Water treatment, HVAC, food & beverage, and pharmaceutical piping.

When to Avoid Water Lines (Prohibitions):

High Pressure (PN > 4.0MPa): Grooves can act as stress risers, leading to flange fatigue.

Metallic Gaskets: Hard gaskets require a smooth (shiny) finish to create a seal.

Hazardous Media: Lethal, highly corrosive, or toxic gases require more secure interfaces like Tongue & Groove (T&G) or Ring Type Joint (RTJ).

V. Common Myths and Best Practices

Myth 1: Deeper is better. Actually, excessively deep grooves can over-compress and damage the gasket. Standardized “Stock Finish” is usually sufficient.

Myth 2: Hand-grinding can fix water lines. False. Manual grinding destroys the precision flatness. Water lines must be restored using professional portable flange facing machines (cold cutting).

Myth 3: Every flange needs water lines. False. High-pressure flanges and those using metal-to-metal seals must be smooth.

VI. The Modern Status of Water Lines

Flange water lines are not obsolete; they have simply become more precise. In modern manufacturing, the Ra 3.2–6.3 μm finish required by ASME standards naturally creates these “water lines” during the lathe turning process. They remain the industry standard for ensuring safety, environmental protection, and operational efficiency in billions of low-pressure connections worldwide.