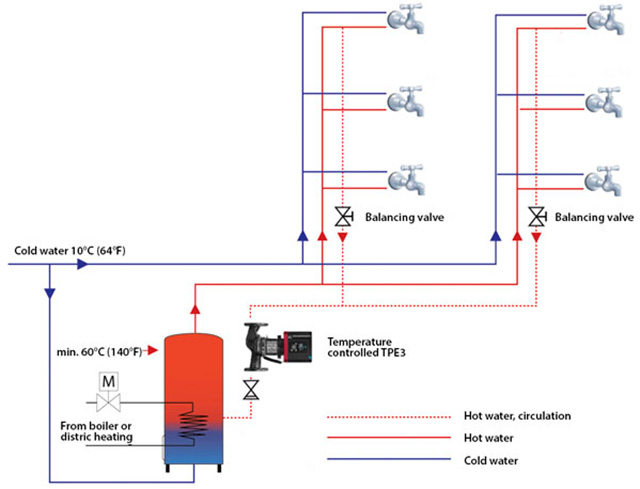

In a large commercial building, a guest in the furthest room should get hot water as fast as a guest next to the boiler room. But physics works against this. Without a properly calibrated balancing valve for hot water return, the water follows the shortest loop, leaving remote branches lukewarm and stagnant.

If you are dealing with tenant complaints or failing health inspections, the issue isn’t your boiler—it’s your hydraulic balance.

Table of Contents

Toggle1. The “Dead End” Problem in Hot Water Loops

Why do we even use a hot water return balancing valve?

In a multi-branch plumbing system, the branch closest to the recirculating pump has the lowest pressure drop. Without resistance, the pump pushes almost all the hot water through this “near loop” and back to the heater. The result? The “far loop” becomes a dead end where water cools down, leading to:

Energy Waste: The pump runs at max speed, but the heat never reaches the destination.

Legionella Risk: Stagnant, lukewarm water (25°C – 45°C) is the primary breeding ground for bacteria.

2. Choosing Between Manual vs. Thermostatic Balancing

When specifying a plumbing balancing valve, you have two primary choices. Here is the field-tested truth about both:

A. The Manual Circuit Setter (Static)

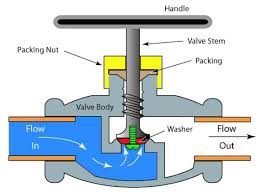

This uses the standard balancing valve symbol—a fixed orifice.

The Insight: It’s great for systems with constant flow. However, as faucets open and close, the pressure in the return line fluctuates. Manual valves can’t adapt, often leading to “over-pumping” just to ensure the last room stays warm.

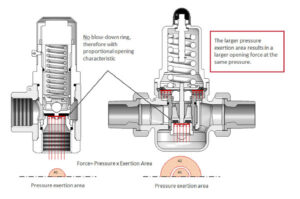

B. The Thermostatic Balancing Valve (Dynamic/Thermal)

This is the “gold standard” for modern hot water balancing valves.

What it does: Instead of balancing by flow (GPM), it has an internal thermal actuator that modulates based on water temperature.

The Benefit: If the return water is hot enough, the valve throttles down. If it cools down, the valve opens up. It effectively turns your entire building into a self-balancing organism.

3. Case Study: Slashing Wait Times from 5 Minutes to 10 Seconds

We recently audited a 12-story apartment complex where top-floor residents reported a 5-minute wait for hot water.

The Observation: The hot water return balancing valve on the lower floors were wide open. The pump was “short-circuiting” through the 1st and 2nd floors.

The Fix: We installed calibrated balancing valves for hot water return on every riser and set them to a calculated $ΔP$.

The Result: We didn’t change the pump or the boiler. By simply redistributing the flow, the wait time at the furthest tap dropped by 90%, and the return water temperature hit a consistent 60°C (killing the Legionella risk).

4. Where to Install? (The Correct Balancing Valve Symbol Placement)

On a P&ID or plumbing schematic, the hot water balancing valve must be placed on each return branch, just before it joins the main return header.

Pro Tip: Always ensure there is a Check Valve installed immediately downstream of the balancing valve. This prevents “back-feeding” where cold water might enter the hot water return line when a high-demand fixture is opened.

5. Maintenance: The Scaling Factor

In hot water balancing valve applications, calcium and scale are your enemies.

Advice: Choose valves with a “self-cleaning” or “dry-dial” design where the mechanical parts aren’t directly encrusted by hard water deposits. If you are using a water balancing valve in a high-mineral area, an annual “flush-out” via the PT ports is mandatory.

Conclusion: Comfort is a Matter of Balance

A balancing valve for hot water return is the difference between a high-performance building and a maintenance nightmare. By ensuring every branch gets its fair share of heat, you protect your tenants, your equipment, and your bottom line.