In the world of fluid control, the butterfly valve is celebrated for its efficiency and cost-effectiveness. However, the most frequent headache for maintenance engineers is internal leakage. When you notice a pressure drop downstream or fluid seeping through a “closed” valve, the culprit is almost always the butterfly valve seat.

The seat is the heart of the valve’s sealing capability, but it is also the most vulnerable component. Understanding why these seats fail can save you thousands of dollars in downtime and replacement costs.

Table of Contents

Toggle1. Chemical Attack: The “Invisible Killer” of Elastomers

A common mistake when searching for a butterfly valve seat is focusing only on pressure while ignoring chemical compatibility.

The Reality: We recently consulted for a plant using EPDM seats in a compressed air system that contained trace amounts of lubricating oil. Within three months, the seats swelled and softened, causing the torque to spike and the seal to fail.

Selection Guide:

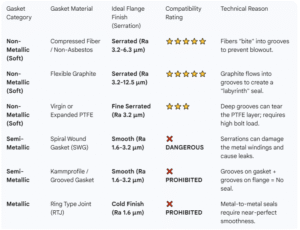

EPDM: Excellent for water, steam, and alcohols, but never use it with oils or petroleum-based fluids.

Viton (FKM): The go-to for high temperatures and oils, though it comes at a premium price.

PTFE (Teflon): Resistant to almost all chemicals, but it lacks the “memory” of rubber and can deform under high-cycle usage.

2. Abrasive Wear: Dealing with Solids and Slurries

If your media contains sand, grit, or crystals, a standard resilient seated butterfly valve is on a countdown to failure.

The Symptom: Fine scratches or “pockmarks” on the seat surface. This happens when particles are trapped between the disc and the seat during closure, tearing the soft material.

The Fix: For abrasive media, don’t just increase the actuator torque to “force” a seal. Instead:

Install a Y-Strainer upstream to catch large particles.

Upgrade to a High-Performance Butterfly Valve with a hardened disc edge or a metal-to-metal seat.

3. Installation Errors: Misalignment and Pinched Seats

Sometimes, a butterfly valve leaking isn’t the fault of the material—it’s the installation.

The Common Error: When installing a wafer butterfly valve, if the pipe flanges are not perfectly centered, the seat will be squeezed unevenly. This creates a “puckering” effect inside the bore.

Field Tip: Always install the valve with the disc in a “slightly open” position. If the valve is fully closed during installation, the flange pressure can pinch the seat edge, causing it to tear the first time the valve is cycled.

4. “Cold Flow” and Compression Set

This is a specific pain point for PTFE seats. Because PTFE is a plastic rather than an elastomer, it can “flow” like putty under constant high pressure.

The Problem: After being closed for a long period, the PTFE seat may not “spring back” to its original shape, leading to a leak the next time it’s closed.

The Solution: Look for seats with an elastomer backup (a rubber ring behind the PTFE). This uses the “memory” of the rubber to keep the PTFE pressed firmly against the disc.

5. Butterfly Valve Troubleshooting Matrix

| Symptom | Potential Cause | Recommended Action |

| Internal Leak (Closed) | Chemical swelling or seat scarring | Verify media compatibility; replace seat material. |

| Increased Operating Torque | Seat swelling or dry friction | Check for oil in EPDM lines; consider lubricated seats. |

| Seat Tearing at Edges | Misalignment during installation | Re-install following diagonal bolt-tightening patterns. |

| Leakage After High Cycles | Material fatigue or “Cold Flow” | Upgrade to RPTFE or a Triple Offset metal seat. |

Conclusion: Matching Material to Media

Preventing butterfly valve leaks starts at the procurement stage. By precisely matching your seat material to your temperature, pressure, and chemical media, you can extend the life of your valves by 3x or more.