Selecting the right y strainer valve body is only half the battle. The most critical decision for system performance is the y strainer filter mesh inside.

If the mesh is too coarse, debris will pass through and damage your ball valves or pumps. If it is too fine, the strainer will clog instantly, causing a massive pressure drop and system downtime. In this technical guide, we break down how to choose the perfect mesh strainer sizes for water, steam, and oil systems.

Table of Contents

ToggleI. Understanding Mesh vs. Micron

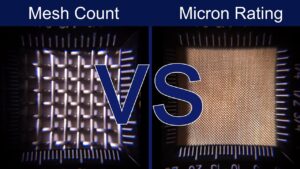

When looking at a y strainer screen, you will encounter two primary units of measurement: Mesh and Microns.

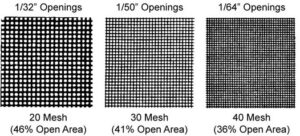

Mesh Count: This refers to the number of openings per linear inch of the screen. For example, a 20 mesh screen has 20 openings per inch. Higher mesh numbers = Smaller holes.

Micron Rating: This measures the actual distance between the wires (1 micron = 1/1,000,000 of a meter).

Key Takeaway: As the mesh size for strainer increases, the particle size it can capture decreases. A 100 mesh screen captures much smaller particles than a 40 mesh screen.

II. Recommended Mesh Sizes by Medium

Based on years of industrial experience, here are the standard y strainer filter recommendations for common fluids:

1. Water Systems (HVAC & Municipal)

For general chilled water strainers or city water lines, the goal is to stop pebbles, pipe scale, and rust.

Recommended: 20-40 Mesh.

Field Insight: For new construction, start with a 40 mesh to catch construction debris (welding slag), then switch to 20 mesh for long-term operation to reduce cleaning frequency.

2. Steam Applications

Steam travels at high velocities and can carry “piping scale” that acts like sandpaper on valve seats.

Recommended: 40-60 Mesh.

The Risk: Steam moves at nearly 100 mph. A mesh too fine will be shredded by “steam cutting.”

3. Oil & Viscous Fluids

Since oil is thicker, a fine mesh can cause the pump to cavitate.

Recommended: 60-100 Mesh (for light oils).

Caution: Always check your pump’s NPSH (Net Positive Suction Head) requirements before selecting a fine mesh for oil suction lines.

III. Screen Materials: Beyond Just “Stainless”

The environment your y-type strainer lives in determines what the screen should be made of:

304 Stainless Steel: The standard for most y strainers for water and general industrial use.

316 Stainless Steel: Essential for marine environments or chemical processing to prevent “pitting” corrosion.

Monel: Used for highly corrosive services like seawater or hydrofluoric acid.

Expert Tip: A high-quality Y-strainer should ideally have an open area ratio of 4:1. This means the total area of the holes in the mesh is 4 times the area of the pipe inlet. This ensures that even if the screen is 50% clogged, the pressure drop remains manageable.

IV. The Relationship Between Mesh and Pressure Drop ($ΔP$)

This is the most important technical factor in strainer valve selection.

Every y strainer filter mesh creates a “restriction” in the pipe. As the screen fills with debris, the open area decreases, and the pressure drop increases.

Rule of Thumb: A clean strainer should not cause more than a 2 psi (0.14 bar) pressure drop. If your y-strainer is constantly clogging, you may need a larger valve body or a coarser mesh.

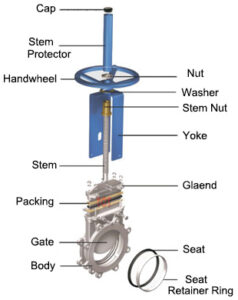

The Solution: Install a ball valve on the blow-off port. This allows you to flush the y strainer screen without disassembling the entire unit.

Warning: For heavy oils, remember that viscosity increases at low temperatures. A mesh that works at 80°C might cause a pump to starve during a cold start at 10°C. If your system operates in cold climates, choose a slightly coarser mesh.

V. Mesh Conversion Chart for Quick Reference

| Mesh Size | Opening (Inches) | Opening (Microns) | Typical Application |

| 20 | 0.0331 | 841 | Large scale, sand |

| 40 | 0.0165 | 420 | General HVAC strainer |

| 60 | 0.0098 | 250 | Steam, light oil |

| 100 | 0.0059 | 149 | Fine chemicals, gas |

VI. Critical Maintenance: The Blow-Off Port

Pro Tip: Don’t just install a plug. Replace it with a Full Port Ball Valve. This allows for “on-the-fly” cleaning (blow-down) without stopping the pump. This single change can reduce your maintenance labor by 70%.

Conclusion

Selecting the correct y strainer filter mesh is a balance between protection and flow efficiency. By understanding the relationship between mesh strainer sizes and your specific fluid medium, you can significantly reduce maintenance costs and extend the life of your ball valves and pumps.

Next Step: Confused about orientation? Read our guide on Horizontal vs. Vertical Y-Strainer Installation.

Get a Quote: Need a custom stainless steel mesh for your Y-strainer? [Contact our technical team].