A swing check valve is a type of non-return valve (or one-way valve) designed to allow fluid to flow in one direction only while automatically preventing backflow.

It plays a vital role in protecting pumps, compressors, and pipelines in industries such as water treatment, power generation, oil and gas, chemical processing, and HVAC systems.

By using a simple and reliable mechanical design, swing check valves ensure safe and efficient operation in both liquid and gas systems.

Table of Contents

ToggleWhat Is a Swing Check Valve?

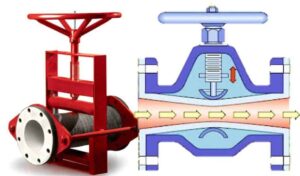

A swing check valve consists of a disc (also called a clapper) that swings freely on a hinge or trunnion.

When fluid flows in the forward direction, the pressure pushes the disc open, allowing the medium to pass through.

When the flow stops or reverses, gravity or back pressure pushes the disc back against the valve seat, closing the passage and preventing reverse flow.

This design makes swing check valves ideal for systems that require automatic operation without external control or power.

Key Components

A typical swing check valve includes the following parts:

Valve Body – The main pressure-retaining part, usually made of cast iron, carbon steel, stainless steel, or bronze.

Disc or Clapper – The moving component that swings open or closed depending on the flow direction.

Hinge Pin / Arm – Connects the disc to the body and allows rotational movement.

Seat – Provides a sealing surface for the disc to rest against when closed.

Bonnet – Covers the internal components and allows access for maintenance.

How Does a Swing Check Valve Work?

The operation of a swing check valve is automatic and depends entirely on the pressure and direction of the fluid.

Forward Flow:

When fluid enters the valve in the correct direction, the pressure lifts the disc away from the seat. This allows unrestricted flow through the valve.Reverse Flow Prevention:

When the flow slows down or starts to reverse, gravity and back pressure force the disc to swing back into the closed position. The disc seals against the valve seat, stopping the reverse flow instantly.

This mechanism helps protect critical equipment such as pumps, turbines, and compressors from potential damage caused by backflow or water hammer.

Advantages of Swing Check Valves

✅ Automatic Operation: No external power or actuator required.

✅ Simple Structure: Few moving parts, easy to maintain.

✅ Low Flow Resistance: The full-bore design minimizes pressure loss.

✅ Reliable Backflow Prevention: Effective in both vertical and horizontal installations.

✅ Versatile Material Options: Available in cast iron, ductile iron, stainless steel, brass, or bronze for different media and temperature ranges.

Disadvantages

❌ Potential for Water Hammer: If the valve closes too quickly, it can cause pressure surges.

❌ Not Suitable for Pulsating Flow: Frequent opening and closing may cause wear on the hinge and disc.

❌ Horizontal Installation Preferred: Vertical mounting may affect closing performance unless designed for it.

Applications of Swing Check Valves

Swing check valves are used in a wide range of industries and systems, including:

Water and Wastewater Treatment – Prevents reverse flow in pumping stations and distribution lines.

Oil and Gas Pipelines – Ensures unidirectional flow of crude oil, gas, and refined products.

Chemical and Petrochemical Plants – Used in corrosive and high-temperature service lines.

Power Generation – Protects condensate and cooling water systems.

HVAC and Fire Protection Systems – Installed in sprinkler lines and booster pump systems.

Installation and Maintenance Tips

To ensure long-term reliability:

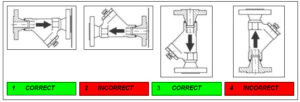

Install the valve in the correct flow direction (usually marked by an arrow on the body).

Avoid rapid pressure fluctuations that may cause valve slamming.

Regularly inspect the hinge, disc, and seat for wear or corrosion.

Ensure the valve is fully supported to prevent vibration damage.

Choose the right material and size based on the working fluid, pressure, and temperature.

Conclusion

The swing check valve is a simple yet highly effective device that ensures one-way fluid flow and prevents reverse flow damage in various piping systems.

With its robust design, low maintenance, and automatic operation, it remains one of the most widely used check valve types in industrial, municipal, and commercial applications.

For systems requiring reliable backflow prevention with minimal pressure loss, the swing check valve continues to be an excellent and cost-efficient choice.