In the heart of any commercial HVAC system—whether it’s a cooling tower, a chiller plant, or an air handling unit (AHU)—water quality is paramount. A single piece of weld slag or scale can destroy a high-efficiency pump or clog a plate heat exchanger.

This is where the hvac strainer becomes the most vital component. In this guide, we discuss how to select and install y strainers for water systems, specifically focusing on the rigorous demands of chilled water strainers.

Table of Contents

ToggleI. Why HVAC Systems Depend on Strainer Valves

An hvac strainer is not just an option; it is a necessity for system longevity. Its primary roles include:

Protecting the Chiller: Modern chillers have micro-channels in their heat exchangers that are easily blocked by debris.

Pump Safety: Preventing gravel or rust from eroding pump impellers.

Maintaining Control Valve Accuracy: Ensuring that ball valves and balancing valves don’t get stuck in a partially open position due to grit.

II. Strategic Placement: The “Strainer + Ball Valve” Unit

For chilled water strainer applications, placement is everything. The industry standard is to create a “Service Header” for critical equipment.

The Standard Pump Suction Configuration:

Suction Side: A ball valve followed by a y strainer. This ensures the pump only “breathes” clean water.

The Maintenance Setup: By installing a ball valve both before and after the strainer in hvac loops, maintenance teams can clean the y strainer screen without draining the entire building’s vertical risers.

Key Term: Chilled water strainer maintenance is simplified by using a “blow-off” ball valve on the strainer’s drain port, allowing for quick flushing of sediment during the cooling season.

III. Selecting the Right Mesh Size for HVAC

In hvac strainer selection, “one size fits all” does not apply. If the mesh is too fine, you increase the pumping cost due to pressure drop. If it’s too coarse, you risk equipment damage.

| HVAC Component | Recommended Strainer Mesh Sizes |

| Centrifugal Pumps | 20 Mesh (Coarse) |

| Cooling Tower Basins | 10 – 20 Mesh (Large debris) |

| Chillers & Heat Exchangers | 40 – 60 Mesh (Fine) |

| Fan Coil Units (FCU) | 60 – 80 Mesh (Very Fine) |

Search Tip: When specifying, always check the y strainer filter mesh material. In chilled water systems, Stainless Steel 304 is the standard to prevent the filter itself from rusting.

IV. Material Selection for Chilled Water vs. Hot Water

Chilled Water Strainer: Typically uses Ductile Iron or Cast Iron bodies with epoxy coating to prevent external sweating and corrosion.

Hot Water / Steam HVAC: Requires Carbon Steel (WCB) or Brass/Bronze to handle the thermal expansion and higher temperatures without leaking at the seals.

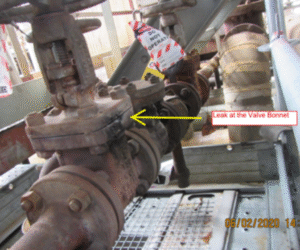

V. Common Challenges in HVAC Filtration

The “Water Hammer” Effect: Rapidly closing a ball valve near a strainer can stress the y strainer filter. Use slow-closing actuators or spring-loaded check valves to mitigate this.

Pressure Drop (ΔP): A dirty strainer y type increases the load on the pump. We recommend installing a differential pressure gauge across the y strainer valve to monitor when it’s time for a cleaning.

Conclusion

Selecting the right y strainer for water in an HVAC context requires balancing filtration efficiency with system pressure. By combining a robust y-type strainer with reliable ball valves, you protect the most expensive parts of your HVAC investment—the chillers and pumps.