Table of Contents

ToggleThe Short Answer: Are They the Same?

If you are confused by the terms non return valve and check valve, you are not alone. Whether you are reading a technical specification from Europe or a purchase order from the United States, you will encounter both terms.

The direct answer is: Yes, they are the same thing.

A Check Valve and a Non Return Valve (NRV) both refer to an automatic valve designed to allow fluid (liquid or gas) to flow in only one direction, effectively preventing backflow. The only real difference lies in regional terminology and industry-specific jargon.

1. Check Valve vs. Non Return Valve: Regional Differences

The primary reason for the two names is geography. Understanding this is key for international procurement:

Check Valve: This is the standard term used in the United States, Canada, and most of the oil and gas industry globally (following API and ASME standards).

Non Return Valve (NRV): This term is the standard in the United Kingdom, Australia, New Zealand, India, and across much of Europe. It is frequently used in water treatment, HVAC, and power generation sectors.

In many engineering circles, the acronym NRV is used as shorthand for any one-way valve, regardless of its specific mechanical design.

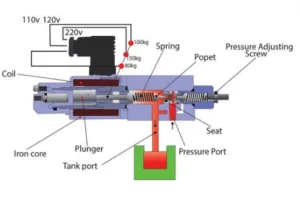

2. Shared Mechanics: How They Work

Regardless of what you call it, the function of a non return valve and check valve remains identical. They are “self-acting” valves, meaning they do not require an external actuator or manual handle to operate.

Cracking Pressure: The minimum upstream pressure required to open the valve.

Flow Direction: The fluid pushes the disc, ball, or flap open as it moves forward.

Backflow Prevention: As soon as the flow stops or reverses, gravity or a spring forces the valve shut, creating a seal that prevents the fluid from returning.

3. Common Types of Check/Non Return Valves

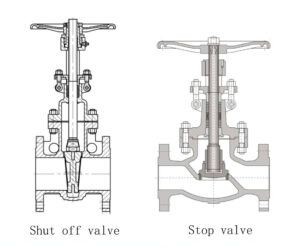

While the names are interchangeable, the designs are not. Depending on your application, you might specify a:

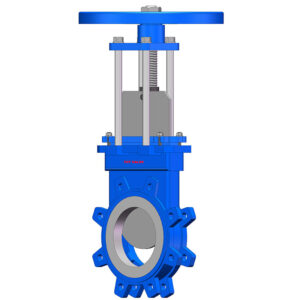

Swing Check Valve: Uses a swinging disc to allow or block flow. Best for full-flow applications.

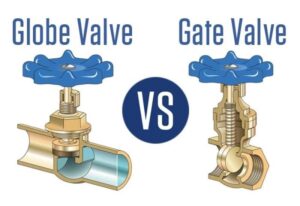

Lift Check Valve: Similar to a globe valve, where the disc lifts off the seat. Common in high-pressure steam services.

Dual Plate/Wafer Check Valve: A compact, space-saving design often used in large-scale industrial water systems.

Ball Check Valve: Uses a weighted ball to seal the orifice, often found in wastewater and viscous fluid systems.

4. Why Technical Clarity Matters

While the terms are synonymous, using the correct terminology in your specific industry can speed up the quoting process. For example:

In Petrochemicals, stick to “Check Valve” to align with API 6D or API 594 standards.

In Municipal Water Works, using “Non Return Valve” or “NRV” will align better with local utility specifications.

Conclusion

Whether you specify a check valve vs. non return valve, the goal is the same: protecting your pumps, compressors, and piping from the damaging effects of backflow. Understanding that these terms are regional synonyms helps engineers and buyers communicate more effectively across borders.

At TOT Valve, we supply high-quality one-way valves to over 50 countries. Whether your project calls for an API Check Valve or a DIN Standard Non Return Valve, we provide the precision and reliability your system demands.