In industrial fluid handling, selecting the correct gasket for a Raised Face (RF) Flange is critical for system integrity. While Polytetrafluoroethylene (PTFE) is prized for its near-universal chemical resistance and thermal range, Virgin PTFE flat gaskets present significant risks when paired with RF flanges.

This technical guide explores the mechanical contradictions between PTFE material properties and RF flange sealing mechanisms.

Table of Contents

Toggle1. PTFE Gasket Variants and Pressure Limits

Understanding the difference between PTFE types is the first step in proper selection:

| Gasket Type | Composition | Pressure Limit (RF Flange) | Best Use Case |

| Virgin PTFE | 100% PTFE Resin | Not Recommended (<0.6 MPa) | Low-pressure, non-critical FF flanges |

| Filled PTFE | PTFE + Glass/Carbon/Graphite | 2.5 – 4.0 MPa | Corrosive media at moderate pressure |

| PTFE Envelope | PTFE Skin + Elastic Core (Graphite/Rubber) | 4.0 – 10.0 MPa | RF Flanges requiring high recovery |

| Metal Reinforced | Metal Core + PTFE Layer | 10.0 – 42.0 MPa | High-pressure industrial pipelines |

2. The Conflict Between RF Sealing and PTFE Properties

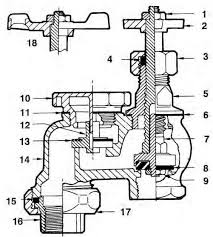

The sealing mechanism of an RF Flange relies on concentrated bolt load on a small surface area (the raised face). This creates high localized stress designed to deform the gasket into the flange’s serrations. Virgin PTFE fails this mechanism for four primary reasons:

A. Poor Recovery (Spring-back)

RF flanges often experience temperature cycling and pressure surges, causing minor flange separation. A reliable gasket must have high recovery to maintain the seal. Virgin PTFE has a recovery rate of less than 10%. Once compressed, it undergoes plastic deformation rather than elastic, leaving gaps when bolts relax or temperatures fluctuate.

B. Cold Flow and Creep

PTFE is notorious for Cold Flow—the tendency of a solid material to move slowly or deform permanently under mechanical stress. On an RF flange, the high-pressure concentration causes the PTFE to “flow” out of the sealing zone. This leads to:

Thickness reduction: Loss of sealing stress.

Adhesion: PTFE remnants bond to the flange face, requiring abrasive cleaning that can damage the flange serrations.

[Image showing the cold flow effect of a PTFE gasket under pressure]

C. Low Blow-out Resistance

Virgin PTFE has low tensile strength (20-30 MPa). In RF applications, the concentrated load combined with internal pipe pressure can “squeeze” or “blow out” the gasket material from between the flanges. This risk increases exponentially at pressures exceeding 1.6 MPa.

D. Low Friction Coefficient (Gasket Slippage)

PTFE has one of the lowest friction coefficients of any solid. RF flanges rely on friction to hold the gasket in place. Under vibration or pressure spikes, a PTFE gasket can slide radially, breaking the seal and causing catastrophic leaks.

3. Engineering Risks in Industrial Applications

Using Virgin PTFE on RF flanges in chemical or petrochemical environments introduces severe risks:

Media Leakage: Especially dangerous for flammable, toxic, or explosive gases.

Increased Downtime: Frequent failures require constant re-torquing and gasket replacement.

Flange Damage: As PTFE flows and adheres, the physical removal process often compromises the flange’s surface finish (Ra), making future seals even harder to achieve.

4. Superior Alternatives for RF Flange Sealing

To benefit from PTFE’s chemical resistance without its mechanical failures, consider these alternatives:

Expanded PTFE (ePTFE): Unlike virgin PTFE, ePTFE has a fibrous structure that significantly reduces cold flow and increases recovery.

Modified (Filled) PTFE: Fillers like Silica or Barium Sulfate reinforce the PTFE matrix, providing better resistance to creep.

PTFE Envelope Gaskets: By using a corrugated metal or graphite core, you gain the “spring-back” needed for RF flanges while maintaining a PTFE-protected surface.

Conclusion: Matching Material to Mechanism

The engineering principle is clear: Material properties must match the sealing structure. While Virgin PTFE is a “miracle” material for chemical compatibility, its mechanical weakness in RF flange configurations makes it a liability. For stable, long-term industrial operations, always opt for reinforced or modified PTFE solutions.