Table of Contents

ToggleThe “Invisible Killers” in Your Pipeline

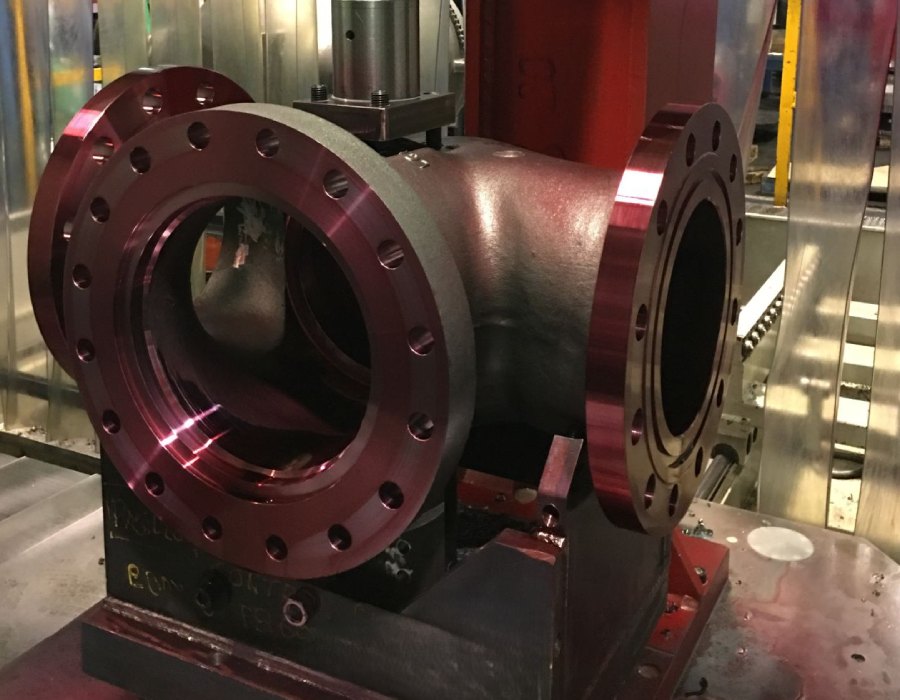

In the world of petrochemicals and power plants, an industrial valve is under constant stress. Inside the thick metal walls of a gate or globe valve, a tiny, invisible crack is a ticking time bomb.

You can’t see these flaws with the naked eye, and you can’t wait for them to leak. This is where Non-Destructive Testing (NDT) comes in. Think of it as a “Industrial MRI” for your infrastructure. By using UT, MT, and PT, we can diagnose the health of the metal without damaging the valve.

Let’s meet the “Audit Team” that ensures your pipeline stays safe:

👨⚕️ Specialist 1: Ultrasonic Testing (UT)

The “Internal MRI” for Deep-Seated Secrets

If a valve body were a human patient, UT would be the MRI scan. It’s the only technology that can “see” through thick metal walls to find what’s lurking in the heart of the casting.

His Superpower: Penetrating power. Whether it’s a 20mm or 200mm thick forged steel body, UT waves dive deep.

What he finds: * Shrinkage & Porosity: The “hollow bones” of a bad casting.

Internal Cracks: The “invisible fractures” that lead to sudden valve body failure.

Wall Thinning: Measuring if corrosion is “eating” the valve from the inside out.

Pro Tip: We use low-frequency probes for cast steel (think: deep bass) and high-frequency for forged steel (think: high-pitched violin) to get the clearest “image” of the interior.

🧲 Specialist 2: Magnetic Particle Testing (MT)

The “Surface Detective” for Ferromagnetic Valves

MT is like a detective who uses “magic dust” to make criminals appear. It’s incredibly fast and pinpoint accurate, but it only works on “magnetic” patients like carbon steel.

His Superpower: High-contrast visualization. By creating a magnetic field, MT forces magnetic powder to “huddle” over even the tiniest surface crack.

What he finds: * Near-Surface Traps: Flaws hiding just 1-2mm under the skin.

Fatigue Cracks: The “stress lines” that appear after years of high-cycle operation.

The Catch: If you have a Stainless Steel valve, this doctor is out of luck. Magnetism is his only tool!

🎨 Specialist 3: Penetrant Testing (PT)

The “Skin Specialist” for Non-Magnetic Materials

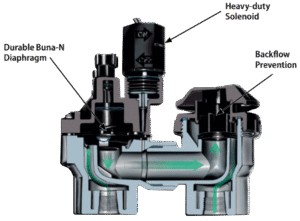

When dealing with Stainless Steel or Copper valves, MT fails, and PT takes the stage. It’s a 3-step beauty treatment that reveals ugly truths.

His Superpower: Capillary action. Using a bright red dye, this method “bleeds” out of surface defects to tell a story.

What he finds: * Pinholes: Those tiny “pores” on the surface of a cast valve.

Grinding Cracks: Micro-cracks caused by improper polishing of the valve seat.

Why it’s cool: It’s low-tech but high-accuracy. As long as the defect “breathes” (is open to the surface), PT will find it.

🏥 The “Joint Consultation”: Why One Doctor is Never Enough

In a real industrial “hospital,” we never rely on just one test. Here is the Valve Diagnostic Protocol:

The “Pre-Op” (Manufacturing): We use UT to check the “internal organs” (the casting) and MT/PT to check the “skin” (the sealing surface).

The “ER” (Installation): We focus on the Weld Seams. UT checks if the bone is fused; PT checks if the surface is smooth.

The “Annual Physical” (Service): We use UT thickness measurement to see how much “weight” (metal) the valve has lost to corrosion.

🛠️ Valve NDT Selection Quick-Ref Table

| If you are checking… | Use this NDT Method | Why? |

| Casting Interior (Porosity/Shrinkage) | UT (Ultrasonic) | Penetrates deep into the valve body. |

| Wall Thickness (Corrosion/Erosion) | UT (Thickness) | Measures metal loss in in-service valves. |

| Carbon Steel Surfaces (Cracks/Folds) | MT (Magnetic) | Fast and highly sensitive to magnetic metals. |

| Stainless Steel Seats (Micro-cracks) | PT (Penetrant) | Best for non-magnetic, precision surfaces. |

| Weld Seams (Incomplete Fusion) | UT + PT | UT for the root, PT for the surface finish. |

🏁 Conclusion: Don’t Guess, Test!

In the world of petrochemicals and power energy, a “healthy-looking” valve can be a disaster waiting to happen. By combining the deep insight of UT, the magnetic precision of MT, and the universal reach of PT, you aren’t just buying a valve—you are buying peace of mind.

Remember: A 15-minute NDT check-up today prevents a 15-day shutdown tomorrow.