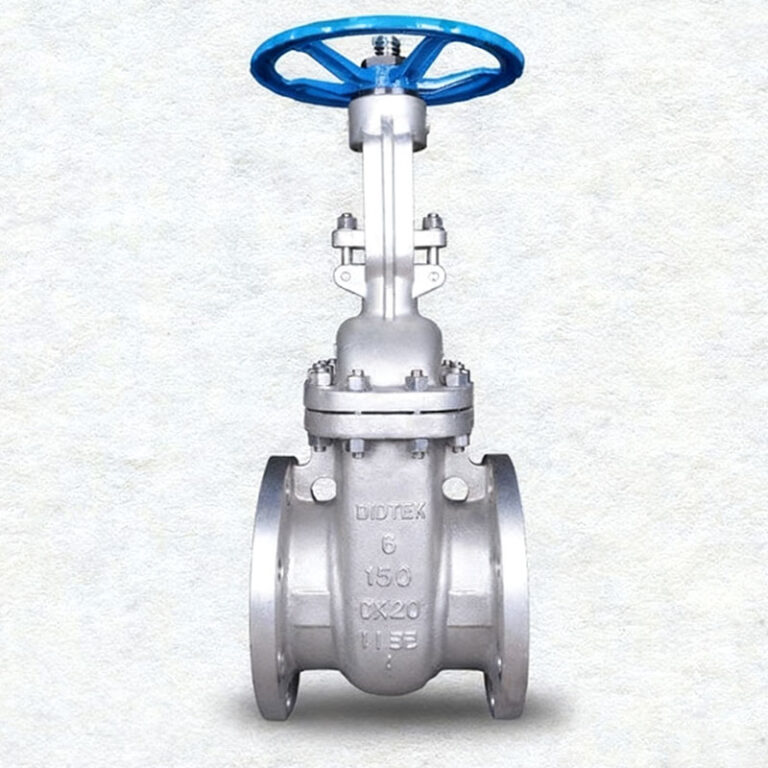

Non-Rising Stem Resilient Seated Gate Valve (Ductile Iron)

The Non-Rising Stem Resilient Seated Gate Valve is a modern isolation valve that overcomes the limitations of traditional gate valves, particularly regarding sealing integrity and corrosion. It is widely recognized for its excellent, leak-tight sealing achieved through a resiliently seated gate, combined with a space-saving non-rising stem design.

It is a reliable and durable solution for controlling fluid flow in a wide variety of industrial and municipal applications.

⚙️ Technical Specifications

| Parameter | Specification | Note/Translation |

| Nominal Size (DN) | DN50 – DN1200 | Range from 2” to 48”. |

| Nominal Pressure (PN) | PN1.0 – PN2.5MPa | Suitable for medium-pressure pipelines. |

| Working Temperature | 0°C – 120°C | Suitable for cold and warm fluids. |

| Applicable Medium | Water | Primarily used for water and general fluids. |

| Actuation Options | Manual, Electric, Pneumatic, etc. | Versatile drive choices. |

🔑 Key Design and Operational Features

- Resilient Seating :

- The gate is completely encapsulated in resilient material, typically EPDM.

- This entire rubber-coated gate utilizes deformation compensation when closed to achieve a superior sealing effect.

- This overcomes the poor sealing, leakage, and corrosion issues common with older metal-seated gate valves.

- Non-Rising Stem :

- The stem threads within the valve body, meaning the overall height of the valve remains constant whether open or closed.

- This effectively saves installation space, making it ideal for buried installations or confined areas.

- Durable Construction:

- Body and gate are made of Ductile Iron , offering high strength and durability.

- The valve is able to withstand high pressure and maintains a tight seal even after extended periods of use, ensuring minimal maintenance.

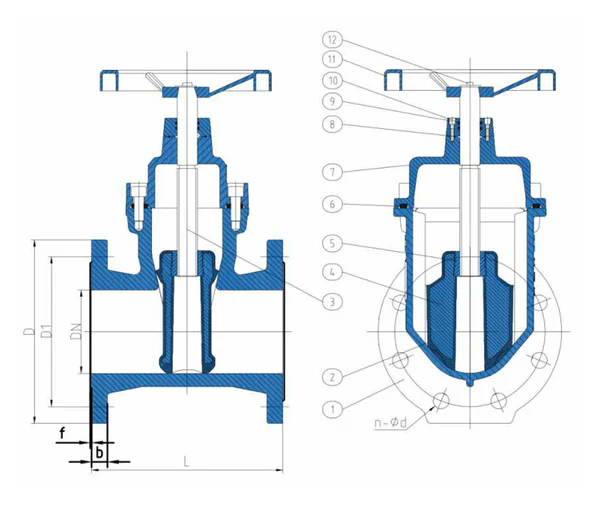

📋 Main Parts Material List

| Item No. | Name | Material |

| 1 | Valve Body | Ductile Iron |

| 2 | Gate | Ductile Iron (EPDM Covered) |

| 3 | Bolts | Galvanized Steel |

| 4 | Sealing Ring | NBR |

| 5 | Bonnet | Ductile Iron |

| 6 | Valve Stem | Stainless Steel |

| 7 | “O” Ring | NBR |

| 8 | Thrust Washer | Tin Bronze |

| 9 | Shaft Bushing | Tin Bronze |

| 10 | Bolts | Galvanized Steel |

| 11 | Bonnet | Ductile Iron |

| 12 | Dust Cover | NBR |

| 13 | Handwheel | Cast Iron |

| 14 | Fastening Nut | Galvanized Steel |

🏭 Application Scope

This valve is widely used as a regulator and shut-off device in fluid pipelines across various systems:

- Municipal Water Supply and Sewage

- Construction and Building Services

- Petroleum and Chemical Industry

- Food, Medicine, Light Textile

- Electric Power, Shipbuilding, Metallurgy, and Energy Systems

This valve provides a modern, reliable, and space-efficient alternative to traditional gate valves in water and general utility services.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.