In municipal wastewater treatment and storm-water management, the biggest enemy of a piping system is debris. Traditional check valves with metal hinges, springs, and seats are prone to jamming, corrosion, and “sticking” when exposed to raw sewage, sand, and silt.

Enter the Industrial Duckbill Check Valve. Designed as a “passive” flow control device, this valve has revolutionized backflow prevention in harsh environments. In this guide, we explore what these valves are used for and why their maintenance-free design is a game-changer for heavy-duty applications.

Table of Contents

ToggleWhat is an Industrial Duckbill Valve?

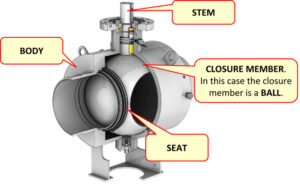

An industrial duckbill valve is a unique, one-piece flexible sleeve shaped like the beak of a duck. Unlike mechanical valves, it operates entirely on the inherent elasticity of its rubber construction and the pressure of the fluid itself.

Forward Flow: As fluid pressure increases, the “lips” of the duckbill open to allow discharge.

Backflow Prevention: When the flow stops or backpressure builds, the lips are forced together, creating a tight seal that prevents reverse flow.

Why “Maintenance-Free” is the Standard for Wastewater

The primary reason engineers specify a rubber duckbill valve over a traditional swing check is the total elimination of mechanical failure points.

1. No Internal Moving Parts

Traditional valves rely on shafts, bearings, and springs. In a wastewater environment, these parts quickly become coated in “ragging” (wipes, hair, and fibers) or seized by grit. Because a duckbill valve is a single piece of molded elastomer, there is nothing to jam or break.

2. Self-Cleaning Action

As the duckbill opens and closes, the flexible rubber expands and contracts. This motion naturally breaks up any dried solids or scale on the valve surface, effectively “self-cleaning” with every cycle.

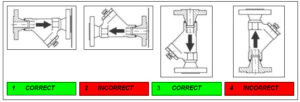

3. Absolute Seal Around Solids

In a metal-seated valve, a single small stone or piece of wood caught in the seat will prevent the valve from closing, leading to total backflow. A duckbill check valve is flexible; the rubber lips can mold themselves around trapped solids to maintain a seal until the next flow cycle flushes the debris away.

What are Duckbill Valves Used For?

While they are highly versatile, these valves excel in specific industrial scenarios:

Municipal Sewage Outfalls: Preventing seawater or river water from flowing back into treatment plants during high tides or storms.

Stormwater Lift Stations: Protecting pumps from the heavy silt and trash load typically found in run-off.

Chemical Processing: When manufactured as a silicone duckbill valve or using Viton, they provide exceptional resistance to aggressive chemicals that would destroy stainless steel internals.

Potable Water Reservoirs: Used to ensure proper mixing and prevent stagnation in large water storage tanks.

Technical Considerations: Slip-on vs. Flanged

When choosing an industrial-grade valve, the mounting style is as important as the material:

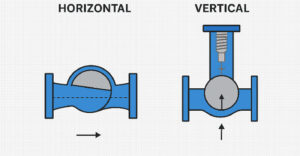

Flanged Duckbill Valves: Designed to be bolted directly to standard ANSI or DIN pipe flanges. Ideal for in-line applications.

Slip-on (Sleeve) Design: These slide directly over the end of a pipe and are secured with heavy-duty stainless steel clamps. This is the preferred method for outfall pipes discharging into open water.

Selecting the Right Elastomer

The longevity of a rubber duckbill valve depends on matching the elastomer to the media:

EPDM: Best for general wastewater and weather resistance.

Neoprene: Excellent for oil-contaminated water and seawater.

Nitrile (Buna-N): The go-to choice for fuel and fats/oils/grease (FOG) applications.