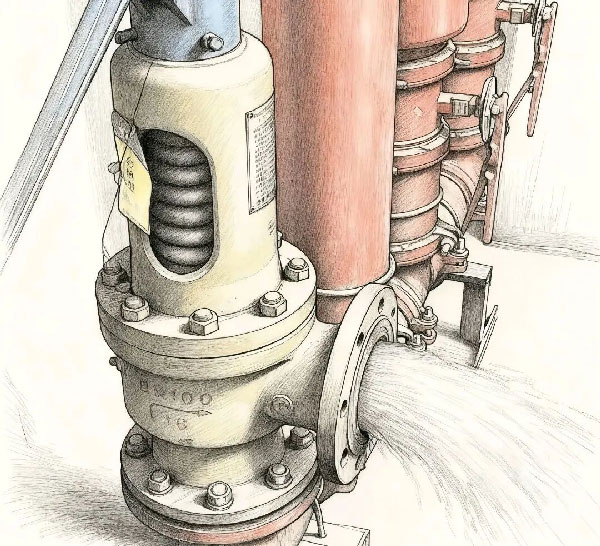

In any pressurized system—be it a massive steam boiler, a chemical reactor, or a cross-country pipeline—the Safety Relief Valve (SRV) is the final line of defense. At the heart of this defense is a single critical parameter: Set Pressure.

Defining the set pressure correctly is the difference between a safe operation and a catastrophic overpressure event. This guide explores the technical essence of set pressure, its relationship with other system pressures, and the international standards governing its calibration.

Table of Contents

Toggle1. What is Set Pressure? (The Technical Definition)

According to ASME Boiler and Pressure Vessel Code (BPVC) and ISO 4126, Set Pressure is the inlet pressure at which a safety valve is adjusted to open under service conditions.

It is the specific point where the upward force of the system media overcomes the downward force of the valve spring (in spring-loaded valves), causing the disc to lift and begin discharging.

Key Distinction: Start-to-Leak vs. Full Lift

Set Pressure: The pressure at which the valve starts to open (audible or visual discharge).

Overpressure: The pressure increase above the set pressure required to achieve full lift and maximum discharge capacity (usually 10%).

2. Pressure Hierarchy: Navigating the Confusion

One of the most common mistakes in procurement is confusing Set Pressure with other operational parameters. Here is the standard hierarchy:

| Term | Definition | Relation to Set Pressure |

| Operating Pressure | The pressure at which the system normally functions. | Must be lower than Set Pressure (typically 90% of set). |

| MAWP | Maximum Allowable Working Pressure of the vessel. | Set Pressure must not exceed the MAWP. |

| Blowdown Pressure | The pressure at which the valve re-seats (closes). | Usually 7% to 10% lower than Set Pressure. |

3. Factors Influencing Set Pressure Selection

Selecting a set pressure isn’t a “guesswork” process; it involves balancing safety margins with operational stability.

A. Temperature Correction (Cold Differential Test Pressure – CDTP)

Safety valves are often calibrated on a test bench at ambient temperature but operate in high-heat environments. Since heat weakens the spring, the CDTP must be adjusted higher than the required service set pressure to account for thermal expansion and spring softening.

B. Backpressure

If the valve discharges into a manifold rather than the atmosphere, Backpressure can oppose the opening of the valve. In such cases, a Balanced Bellows Safety Valve is required to ensure the set pressure remains constant regardless of downstream conditions.

C. Media State (Liquid vs. Gas)

Set pressure behavior varies between compressible fluids (gas/steam) and non-compressible fluids (liquids). Gas service valves typically have a “pop” action, while liquid service valves exhibit a gradual lift.

4. International Standards & Calibration Limits

Global compliance requires strict adherence to tolerance levels. Most international projects follow ASME Section VIII or EN ISO 4126:

Tolerance Limits: * For pressures ≤ 70 psi (5 bar): Tolerance is ± 2 psi (0.15 bar).

For pressures > 70 psi (5 bar): Tolerance is ± 3% of the set pressure.

Mandatory Testing: Valves must undergo a “Pre-set” test, a “Leakage” test, and a “Re-seating” test before being tagged with a lead seal.

5. 3 Common Mistakes in Set Pressure Specification

Setting Too Close to Operating Pressure: If the set pressure is only 5% above the operating pressure, the valve will suffer from “Simmering” or frequent leakage, damaging the seating surfaces.

Ignoring the Spring Range: Every spring has a specific “Pressure Range.” Trying to adjust a valve far outside its spring’s design limit will lead to unstable performance.

Neglecting Periodic Recertification: In most jurisdictions, safety valves must be recertified annually. Corrosion, vibration, and spring fatigue can cause “Set Pressure Drift.”

Conclusion: Engineering Peace of Mind

Set pressure is the “soul” of the safety valve. By correctly specifying this parameter according to your vessel’s MAWP and operating conditions, you protect not only your equipment but also the lives of the personnel on-site.